Water damage in collision repair presents significant challenges, impacting structures, equipment, and vehicles. Common entry points include open doors, windows, and faulty roofing. Once inside, moisture can cause mold growth and structural damage, necessitating complex repairs. Prompt action is crucial to minimize secondary damage. Specialized drying tunnels are essential for effective water damage restoration, expediting drying times and enabling detailed repairs like auto frame work and painting. Best practices for tunnel usage include proper ventilation, specialized drying agents, regular cleaning, and staff training for enhanced repair efficiency, quality outcomes, and customer satisfaction in water damage collision repair services.

Water damage is a frequent concern in collision repair shops, leading to costly delays and repairs. Understanding the role of drying tunnels is essential in mitigating this issue. This article explores how these innovative tools help combat water damage in collision repair settings. We’ll delve into their functionality, benefits, and best practices for effective utilization, emphasizing the importance of quick and efficient drying processes in ensuring top-quality repairs and minimizing business disruptions.

- Understanding Water Damage in Collision Repair Shops

- The Functionality and Benefits of Drying Tunnels

- Best Practices for Utilizing Drying Tunnels Effectively

Understanding Water Damage in Collision Repair Shops

Water damage is a significant challenge faced by collision repair shops, as it can cause extensive car damage repair and disrupt operations. When water infiltrates a shop, it doesn’t just affect the physical structure; it poses risks to valuable equipment, sensitive electronic components, and finished vehicles under repair or in inventory. Understanding the nature of water damage is crucial for effective mitigation and prevention strategies.

In collision repair shops, water can infiltrate through various entry points like open doors, windows, or faulty roofing systems. Once inside, moisture can quickly transform into a breeding ground for mold and mildew, damaging surfaces and posing health risks to employees and customers alike. Moreover, water damage often goes beyond visible surface levels; it can penetrate walls, floorboards, and even the framework of vehicles, leading to complex car repair services. Prompt action is essential after any water incident to minimize secondary damage and ensure a safe, efficient workspace for auto detailing and restoration processes.

The Functionality and Benefits of Drying Tunnels

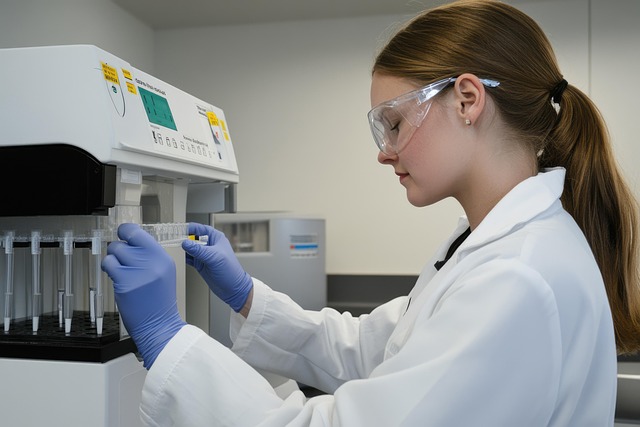

Water damage collision repair is a specialized service required when vehicles sustain inundation during accidents or natural disasters. In these scenarios, drying tunnels emerge as indispensable tools for restoring vehicles to their pre-damaged condition. These innovative systems are designed to expedite the drying process, ensuring efficient removal of moisture from auto frames and interiors.

The primary functionality of drying tunnels involves circulating heated air through a vehicle’s compartments at high velocity. This strategic airflow facilitates the rapid evaporation of water, preventing mold growth and structural damage. Beyond their practical benefits, these tunnels offer significant advantages for collision repair shops. They streamline the restoration process, reducing turnaround times and enabling technicians to focus on more intricate tasks like auto frame repair and meticulous auto painting.

Best Practices for Utilizing Drying Tunnels Effectively

In water damage collision repair, drying tunnels are a critical component for restoring vehicles to their pre-incident condition. To maximize their effectiveness, several best practices should be followed. Firstly, ensure proper ventilation within the tunnel to facilitate efficient air circulation and rapid drying of vehicle interiors. This is crucial as adequate airflow helps prevent mold growth and odour retention. Secondly, utilize specialized drying agents or desiccants, such as silica gel packets or absorbent materials, to accelerate the dehydration process. These agents help absorb excess moisture from hard-to-reach areas and surfaces.

Additionally, regular cleaning and maintenance of the drying tunnel itself are essential. Regularly inspecting and replacing filters, cleaning ductwork, and removing any accumulated debris ensures optimal airflow and performance. Proper training for staff on operating and maintaining the drying tunnel is also vital. Following these practices not only enhances the efficiency of water damage collision repair but also contributes to better quality outcomes, ensuring satisfied customers and a more reliable auto collision center.

Drying tunnels play a pivotal role in mitigating water damage within collision repair shops, ensuring efficient and effective restoration. By understanding the impact of water damage and implementing best practices for tunnel usage, professionals can significantly enhance the speed and quality of their repairs. This not only benefits businesses but also guarantees customer satisfaction by reducing downtime and minimizing secondary damages caused by moisture. Incorporating drying tunnels into collision repair workflows is a strategic move towards successful water damage management.